Optimising your non-destructive testing (NDT) processes is at the heart of our mission at BABBCO.

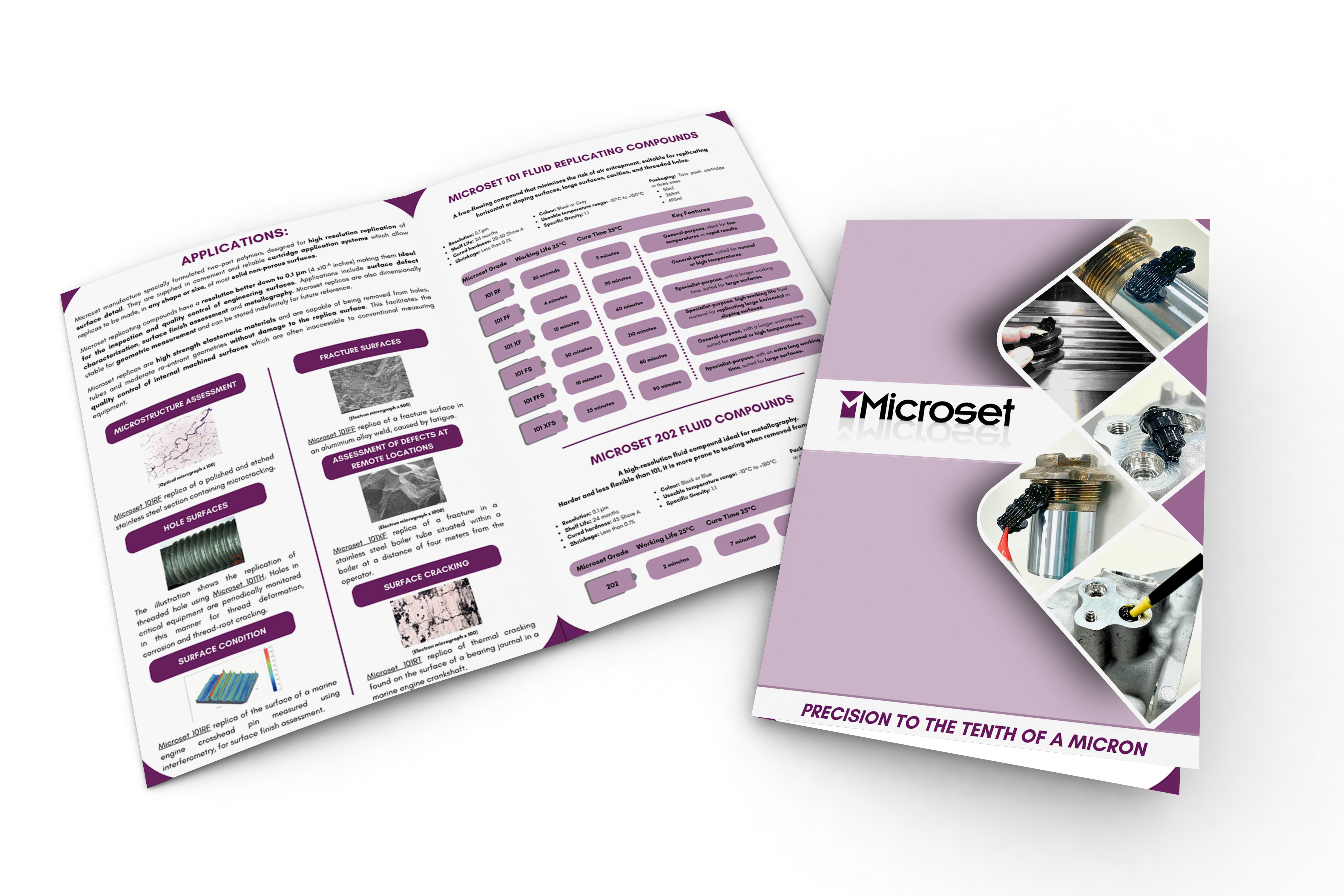

We are proud to present our brand new method: surface replication, made possible by the Microset range of high-resolution products.

Microset: excellence in surface replication, now available from us

We are delighted to announce the addition of the Microset brand to our already well-established catalogue. Microset, renowned for the quality and precision of its replication materials, complements our existing range by providing a unique solution for detailed surface analysis.

Applications of Microset products

The Microset range, now offered by BABBCO, allows for a wide range of industrial applications thanks to its various compounds.

- Dimensional control of internal or external shapes: Microset replication compounds enable accurate impressions to be taken of complex geometries, such as threads, gears or bores. This method is essential for quality control and reverse engineering, as it allows dimensions to be measured and ensures that parts comply with specifications without having to be dismantled.

- Evaluation of surface defects and surface finish quality: Replication allows the smallest details of a part's surface to be captured with a high degree of accuracy, including defects such as corrosion, micro-scratches or wear. Once the impression has hardened, it can be analysed in the laboratory using a microscope or other instruments, providing an objective and reproducible assessment of the surface condition.

- Quality control of internal surfaces and dimensions: For parts with cavities, ducts or areas that are difficult to access, surface replication is an ideal solution. The fluid compounds flow into every nook and cranny, creating a faithful replica of the internal surface for easy inspection outside the part.

- Crack detection and metallography: Certain Microset products, such as Microset 202, have a high hardness that makes them suitable for metallography. They can be used to create microstructure impressions of materials, which is crucial for detecting cracks, stresses or deformations at the microscopic level, particularly in aeronautical or mechanical engineering applications.

Surface replication: a complementary and powerful NDT method

Surface replication is an NDT technique that involves creating a faithful impression of a component's surface. Once hardened, this replica can be analysed in the laboratory using various techniques (optical microscopy, scanning electron microscopy, etc.) to assess the surface condition, detect defects, or analyse the microstructure of the material without damaging the original part.

This method offers many advantages:

- High resolution: captures micrometric details of the surface.

- Accessibility: allows inspection of hard-to-reach areas.

- Non-destructive: preserves the integrity of the inspected part.

- Laboratory analysis: provides a controlled environment for accurate evaluation.

- Documentation: provides a permanent record of the surface condition at a given point in time.

- Fast: the process of creating the replica is generally quick, minimising downtime.

Discover the Microset range: solutions tailored to your needs

Microset offers a range of high-resolution two-component silicone replication products designed for a variety of applications:

- MICROSET 101 FLUID : These fluid compounds are ideal for replicating metal surfaces, even rough ones, cavities, tubes and threaded holes. Their low viscosity minimises the risk of air bubbles and facilitates application over large areas.

- MICROSET 101 THIXOTROPIC : Thanks to their thixotropic nature, these compounds can be applied to vertical and overhead surfaces without running, ensuring accurate replication of hard-to-reach areas.

- MICROSET 202 : These fluid compounds offer superior hardness and less flexibility compared to the 101 range. They are particularly suitable for replicating metallurgical microstructure, rough surfaces, cavities, tubes and thread profiles.

- MICROSET 121 FORMING PUTTY : This two-component synthetic rubber modelling putty is designed for macroscopic moulding of surface shapes and profiles. The two components are mixed by hand in equal quantities, and the mixture is then pressed against the surface to be replicated.

Available in two versions: 121F for fast curing and 121S for slow curing, for easy use over a wide range of temperatures.

Complete your NDT kit with Microset replication

The inclusion of the Microset range in our catalogue demonstrates our commitment to providing you with the most effective and versatile tools for your non-destructive testing needs.

Surface replication, thanks to the precision of Microset products, complements our existing methods by offering a unique and detailed perspective on the condition of your materials.

Don't wait any longer to explore the possibilities offered by Microset surface replication.

Discover our complete range of replication products now on our webstore.

Our team is at your disposal to advise and assist you in choosing the solution best suited to your applications.