News & Expertise

The BABBCO webstore is now available in new European countries.

Microset surface replication is a new non-destructive testing method offered by BABBCO. It allows you to quickly create a high-resolution impression of surfaces for detailed laboratory analysis without

Socomore is proud to announce its acquisition of Microset Products Ltd, a UK-based company specializing in advanced replication materials for engineering inspections. This strategic move enhances Socomore's

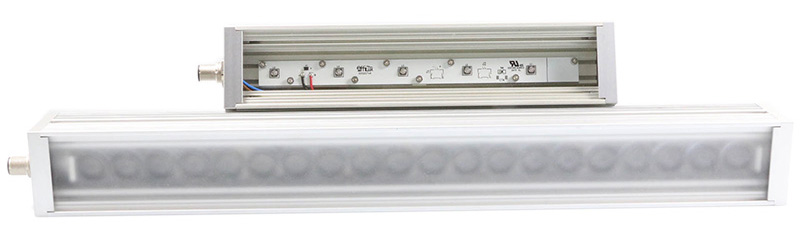

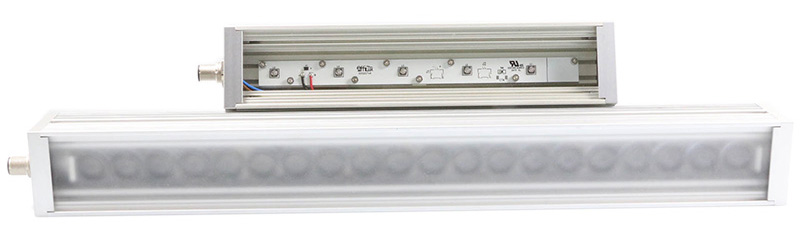

UFLEX is the perfect luminaire for large-area ultraviolet lighting.

This tailor-made range adapts to the areas to be lit, whatever the surface and distance. Its lightweight, robust design is suitable for

As part of its services for the production and magnetic particle inspection reference parts in accordance with XP CEN/TS 17100, BABBCO is equipped with the most advanced lighting systems on the market.

Discover the benefits of purchasing automotive NDT consumables in Italy from a Level 3 NDT supplier

Find out why certified consumables are essential for non-destructive testing in the Italian aerospace industry.

Discover the selection criteria and tips for buying high quality NDT consumables for aerospace in Italy

Discover the benefits of using NDT services in the Italian aerospace industry, including early defect detection and reduced maintenance costs